What are the advantages of a gravity system?

No pumping whatsoever is carried out at Château Pédesclaux, from the arrival of the grapes in the vat house right through to bottling. The transferral process is carried out using a gravity system thanks to the natural incline of the terrain and the use of four elevated vats.

During the vinification and ageing stages, the wine is particularly fragile and it is for this reason that we opt to use a less traumatic transferral system than pumping for our grapes and wines.

Studies have shown that the use of a pump on the crops can have an influence on the taste of the wine as it significantly increases astringency and bitterness.

Our gravity system enables us to limit the phenomena of crushing the crops and also to reduce pressure on the musts and wines. The original qualities of the wine (texture, balance, aromas) are thereby preserved.

Comment fonctionne ce système?

1/ Fermentation

The first stage of vinification consists of placing the grapes in the upper part of these dual-compartment truncated vats. Under the pressure of the carbon dioxide that is produced during alcoholic fermentation, the marc (compact mass composed of the seeds and skins of the grapes) is pushed back up towards to the top of the vat where it forms a layer known as the ‘marc cap’. The pressure results in cracks appearing in the cap which may act as potential preferential channels.

2/ Rack and return

During extraction, and in order to prevent the wine from passing through the preferential channels, we carry out the process of rack and return. The marc is separated from the wine by gently emptying the upper part of the vat using gravity. When all of the juices are emptied, the cap which was floating on the top moves down to the base of the vat and decompresses through gradual drainage. The marc and wine thereby remain as such in these two separate compartments for one hour or sometimes overnight.

3/ Gravity transfer

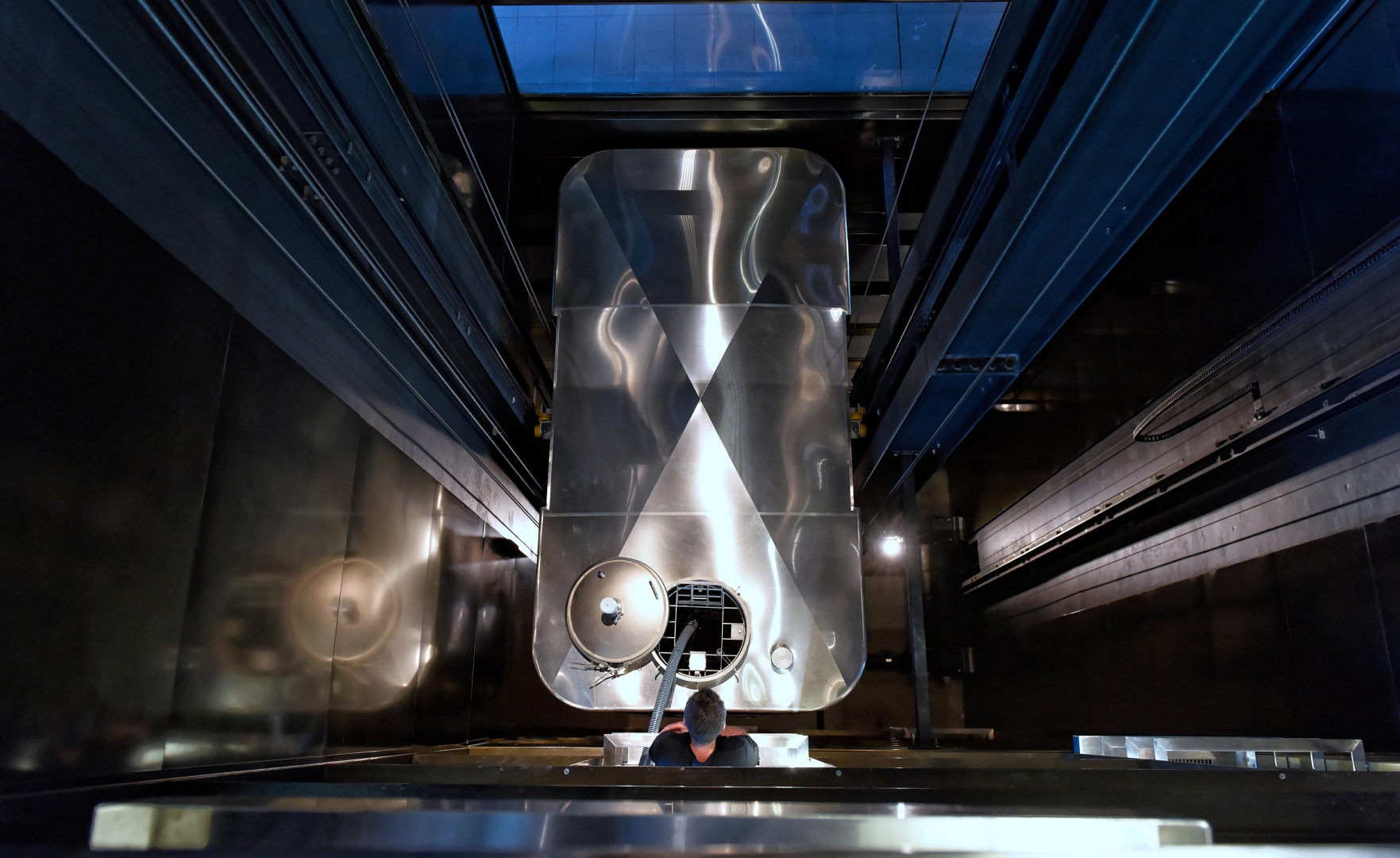

Once the marc and the musts (the liquid part) have been separated, we place the musts ready for fermentation in one of the 4 elevated vats which, when full, weighs almost 14 tonnes. The vat is elevated to a height of 7 metres so that it reaches the upper level.

4/ Reverse rack and return

The musts are then gradually diffused ‘like rainfall’ from the top of the vat and across the marc cap, gently and without pressure. The marc cap therefore slowly rises upwards thereby ensuring that musts are diffused gradually through the marc. This stage helps to enrich the wine’s substance (tannins and anthocyanins).

Optimum extraction

The frequency of these interventions varies depending on the characteristics of the parcels and the vintage. We, therefore, repeat the cycle up to 4 times a day for 4 to 6 days which enables gentle, consistent and homogenous extraction of the tannins, and with as much precision as possible thanks to the tasting of the vats after each intervention.

If these topics interest you, we invite you to join our newsletter by entering your email below.