A tool to mature our wine that works in harmony with the barrels

At Château Pédesclaux, we are continually working to make all our activity more environmentally friendly. So, we have decided to explore the possibilities that amphorae offer when it comes to the maturation process.

We already work hard to preserve the unique character of our grapes and our wine – in particular, our gravity-flow system helps with this. Still, thanks to this new tool, we are able to take that work to the next level.

Last December, we installed five clay amphorae and sandstone eggs in our winery, beside the oak barrels. They were carefully chosen from three different manufacturers, and the 2020 vintage will serve as a basis for the experiments we intend to conduct on all of them, to compare their relative utility.

The benefits of maturation in amphorae

These clay containers were the most important tool for making and maturing wine that the winemakers of antiquity possessed; for some years now, their popularity has been on the rise once again. They are very interesting from a technical perspective, because they foreground the purity of the fruit – but also from a historical perspective, because they allow us to reconnect with the traditions of our forebears.

These new receptacles offer an amazing opportunity to experiment. The original impetus for this project was a consideration of the ways that new oak affects our wines; that was what led us to make this choice.

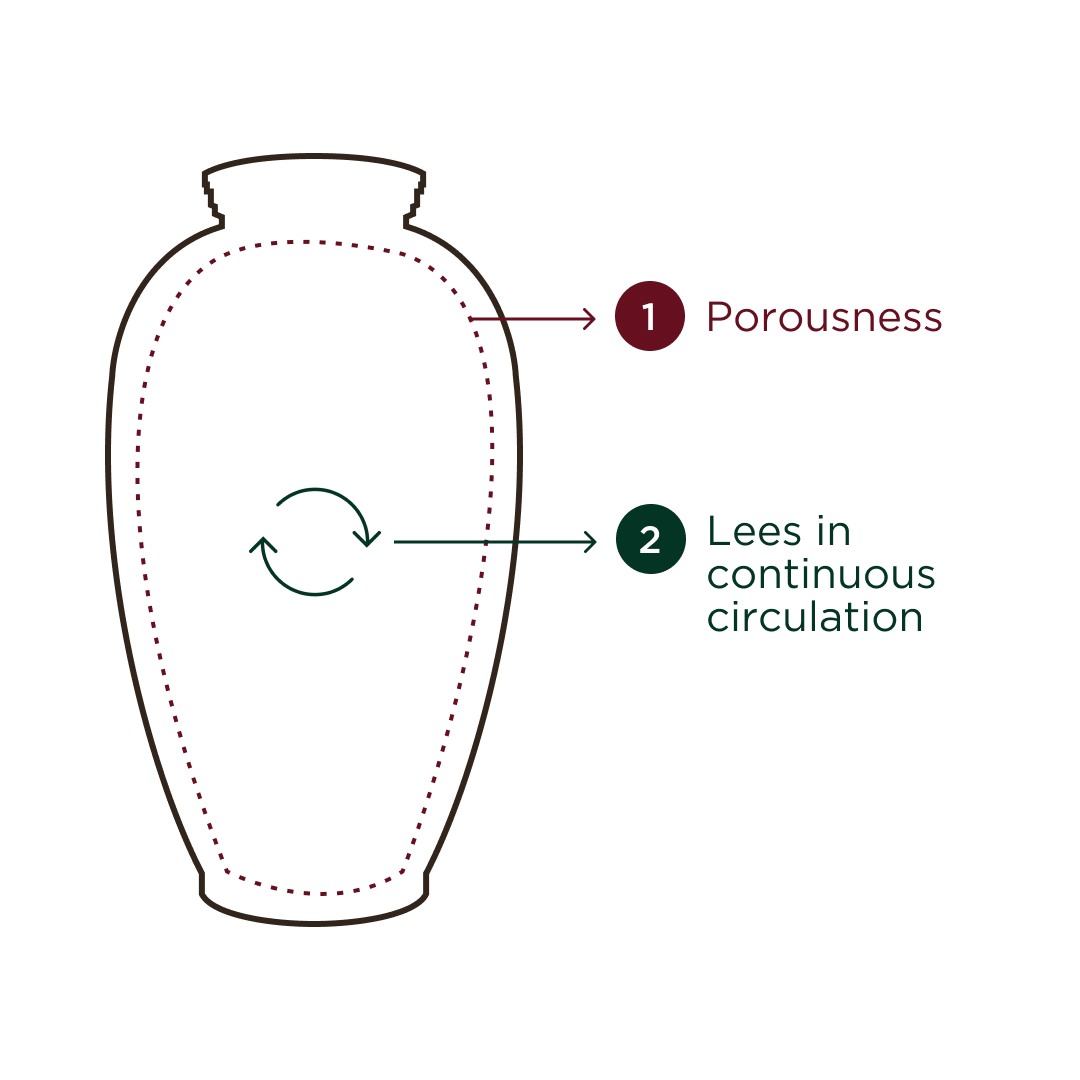

Here is a diagram that shows more clearly what happens: how the porous surface allows oxygen exchange and the way the convection currents move through the wine as it matures:

1. Porousness – it could be said that the clay and the sandstone ‘breathe’: they allow tiny quantities of oxygen to enter, which enables the micro-oxygenation of the wine without adding any oak aromas. However, the levels of oxygenation and evaporation are both much lower than with new oak, and this means that, later in the process, we need to add considerably less sulphur to protect the wine.

The level of porosity depends on the material and the way that heat is applied to it. The hotter the receptacle becomes, the less air can get through its pores. The oxygen that does pass through softens the tannins and brings tension and freshness to the wine.

2. Lees in continuous circulation – the shape of the amphorae, which are entirely without angles, sets the wine in continual motion: this is a natural way to keep the lees in suspension, which makes the wine rounded and supple and conserves its freshness.

A carefully managed process

For this experimental process, we will use our first and second wines. We are going to observe, taste and compare in detail the influence of these containers on the 2020 vintage, using heat levels and materials that will vary according to the producer’s advice. All of these amphorae are made by hand. They are fragile objects that require very careful handling.

For our amphorae and sandstone eggs, we rely on three different producers: Tava and Sirio, two renowned Italian artisans, and Biopythos, based in Limoges.

Our team visited the Biopythos workshop in order to gain a better understanding of how these receptacles are made and to gain an appreciation of the dynamics of a small business that is adapting the tradition of Limoges porcelain to accommodate this new trend.

How an amphora is made – see behind the scenes:

If the trials are successful, we will scale them up, harmonising the use of amphorae and barrels so that each enhances the performance of the other.

Please join our newsletter in order to receive our last articles.